GRIPMetal™

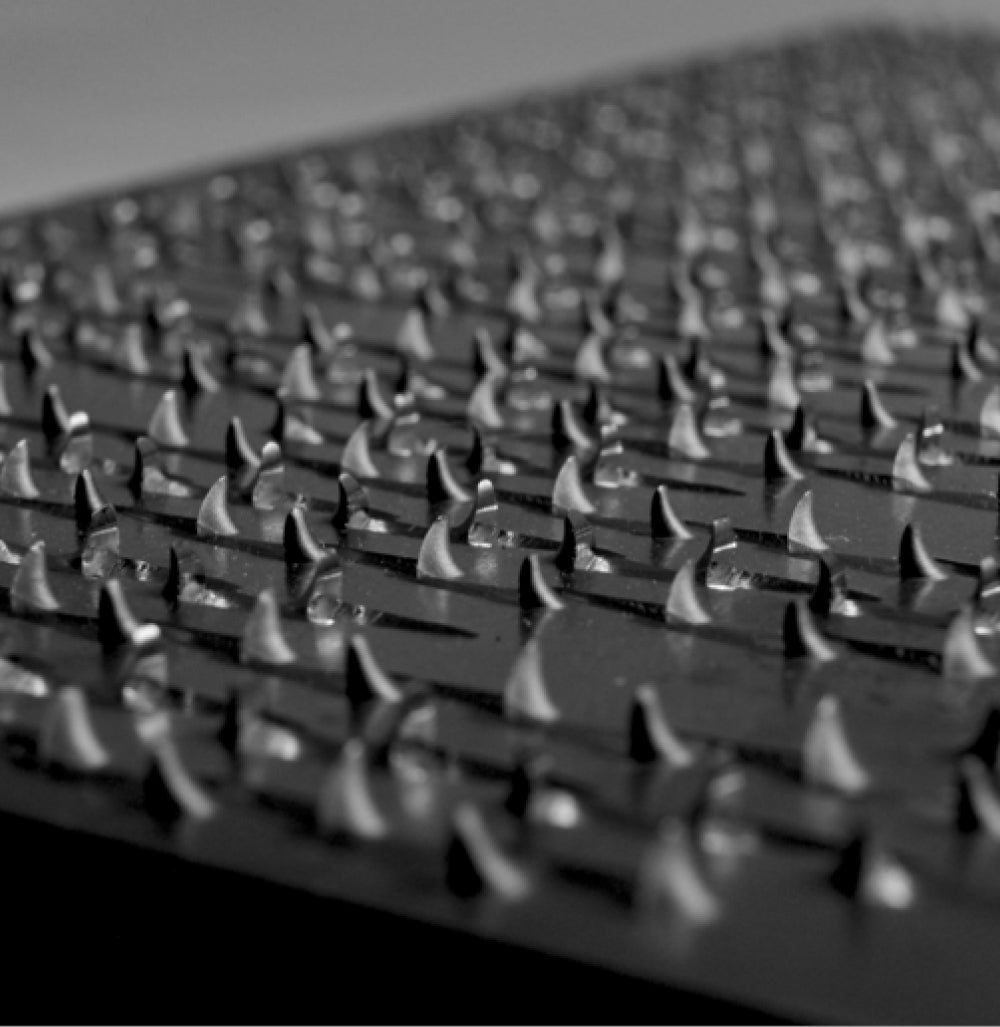

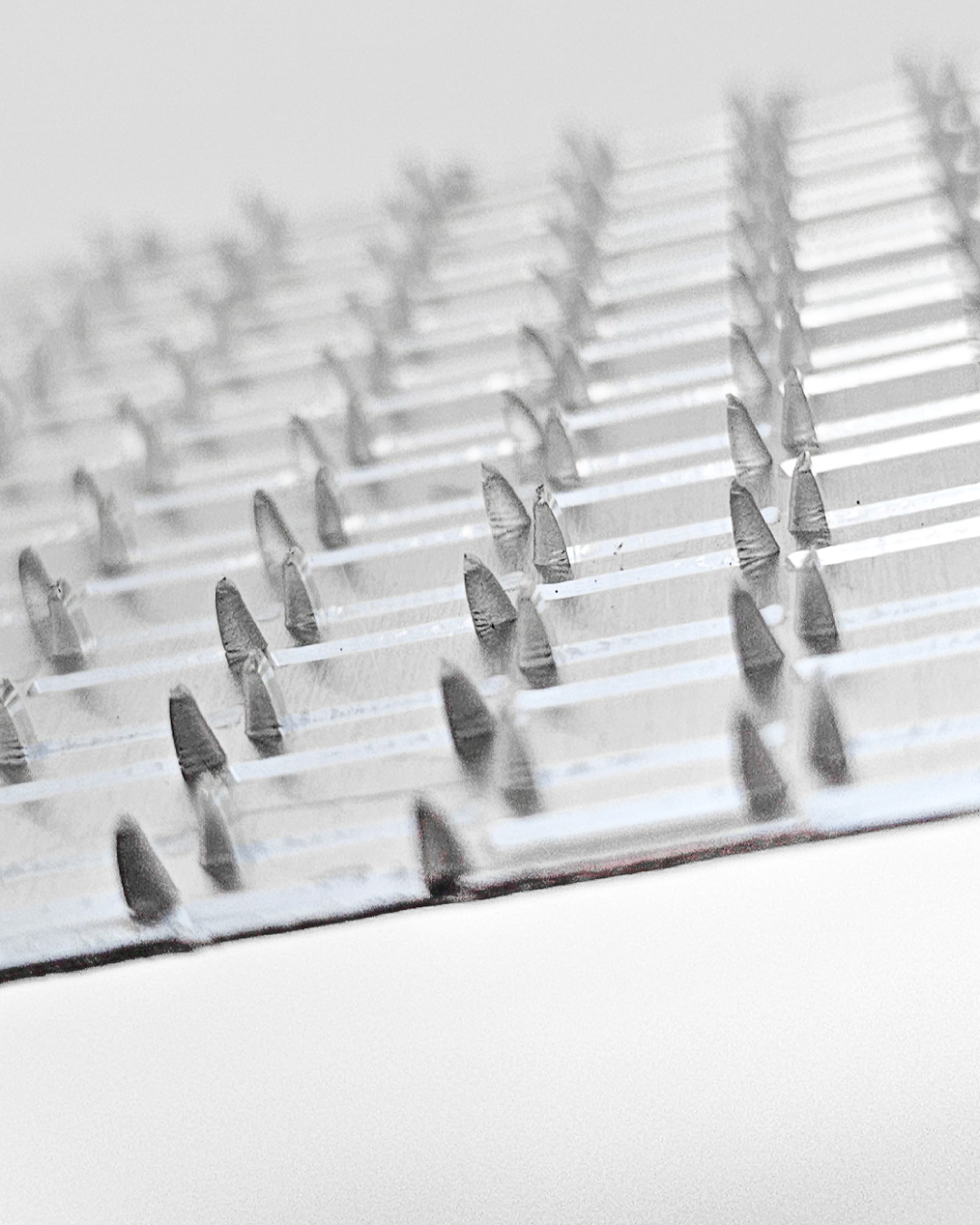

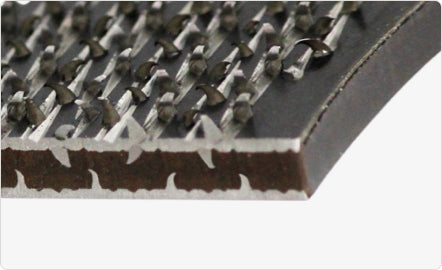

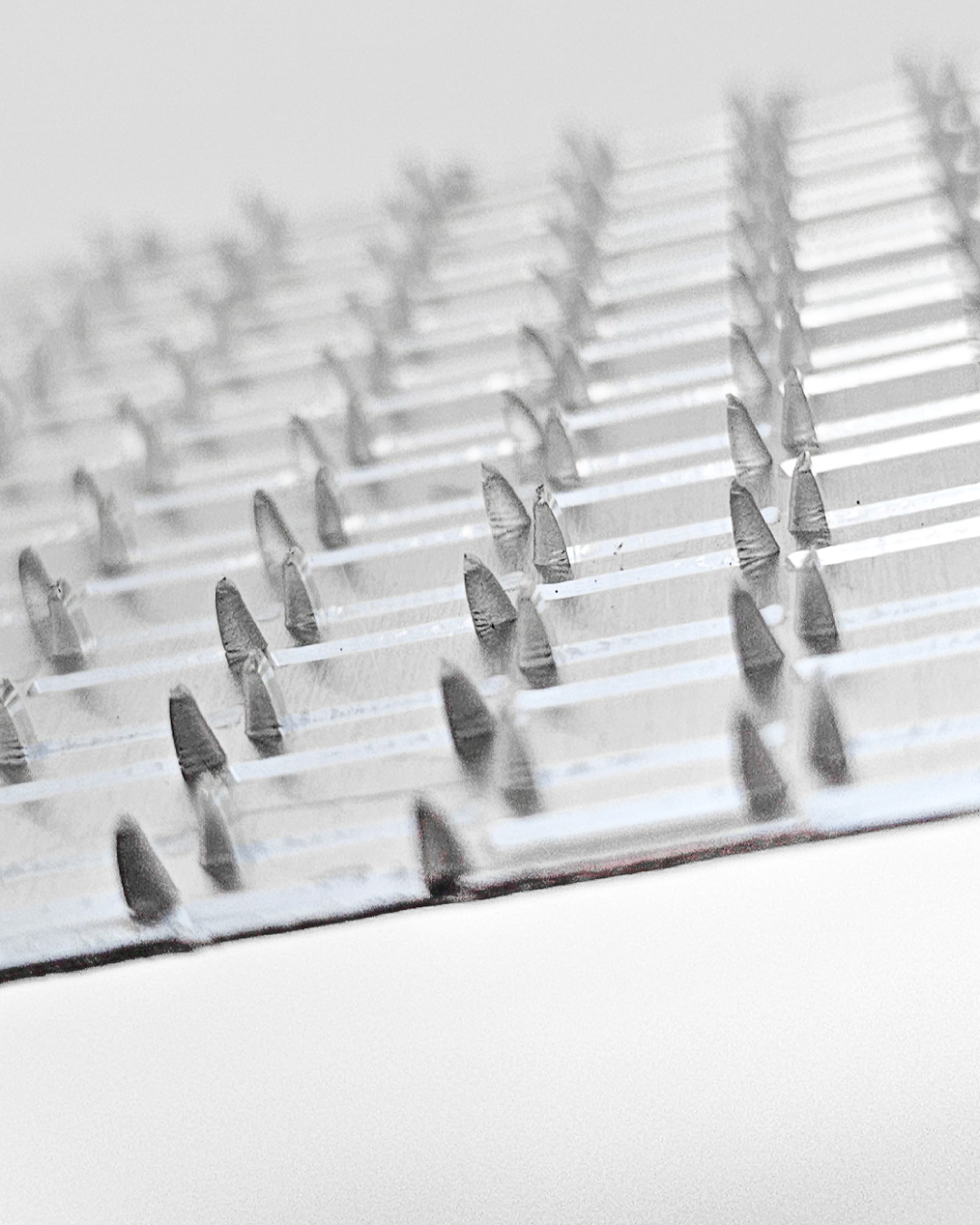

An innovative patented technology of metal hooks distributed either on one side, or both sides of thin gauge metallic sheets.

See what makes GRIPMetal™ the best choice for all sectors of industry.

Mechanical Attachment

The technology that drives GRIPMetal™ stems from the NUCAP© Retention System (NRS™). This patented technology won the automotive PACE award in 2001 and is now the premiere Mechanical Attachment Technology in the world.

Structural Reinforcement

GRIPMetal™ is an innovative technology for a mechanical bonding between material layers based on a patented technology for the mass production of consistent small-scale metal hooks that are distributed either on one side or both sides of thin gauge metallic sheets.

Composite Materials

The GRIPMetal™ composite concept increases structural performance while optimizing weight. A composite can be constructed in 3 methods, with GRIPMetal™ acting as a structural layer, reinforcing the core or forming high strength outer skins.

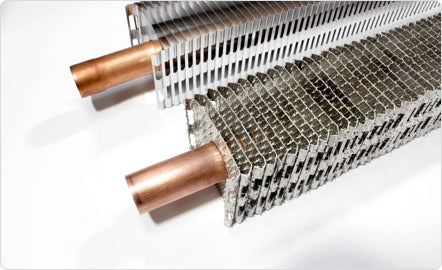

Thermal Enhancement

With GRIPMetal and our unique and patented process creates surface enhancement to any metal, increasing the surface area without adding weight to an element, which allows manufacturers to reduce the size and weight of their products.

GRIPMetal™ technology can be produced in any Metal Substrate

-

STEEL

-

ALUMINUM

-

COPPER

-

BRASS

-

TITANIUM

GRIPMetal™ can be fabricated with a variety of materials and composites

Featuring precisely designed hooks that give designers, engineers and scientists a brand-new foundation for design and manufacture of complex forms in composites, GRIPMetal transfers the core strengths of a metal substrate to other materials. Consisting of a consistently shaped field of micro-scaled hooks that are formed onto ultra-thin gauge sheet metals, using robust mechanical adhesion to overcome the challenges of bonding different materials together.

Potential applications range from strengthening thin-gauge composite materials in papers, woods and plastics, to large- scale use in construction technologies and materials.

-

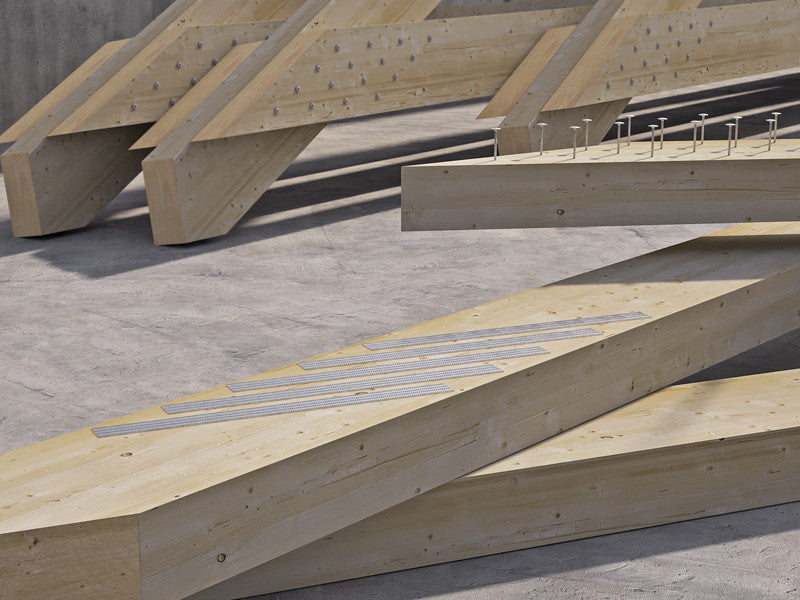

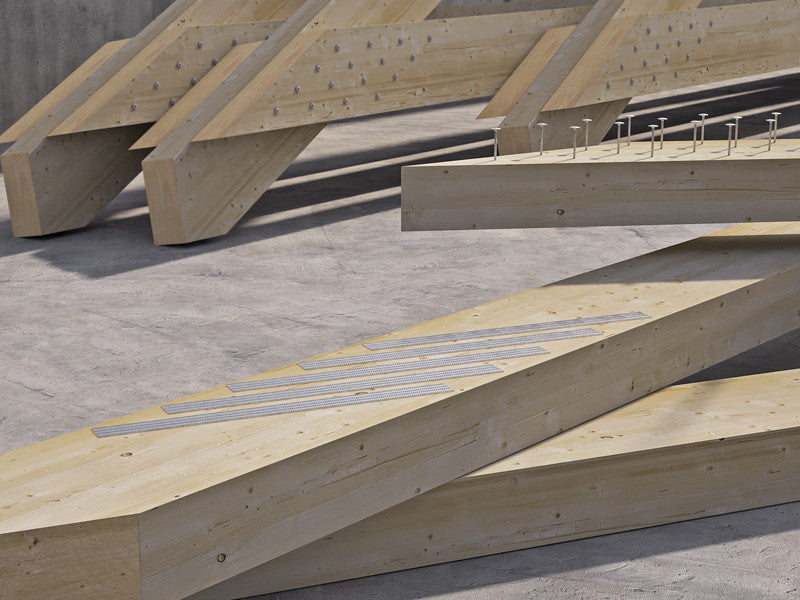

EZBlocks

EZBlocks

Lightweight CLT Blocks reinforced with GRIPMetal™

EZBlocks is a Cross Laminated Timber (CLT) block that boasts all the benefits of traditional construction but in a lightweight, strong, and renewable way.

-

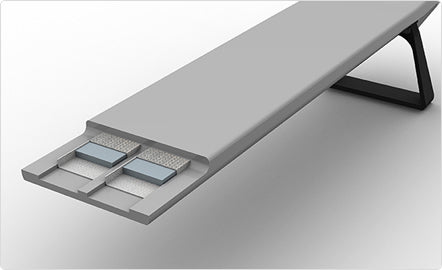

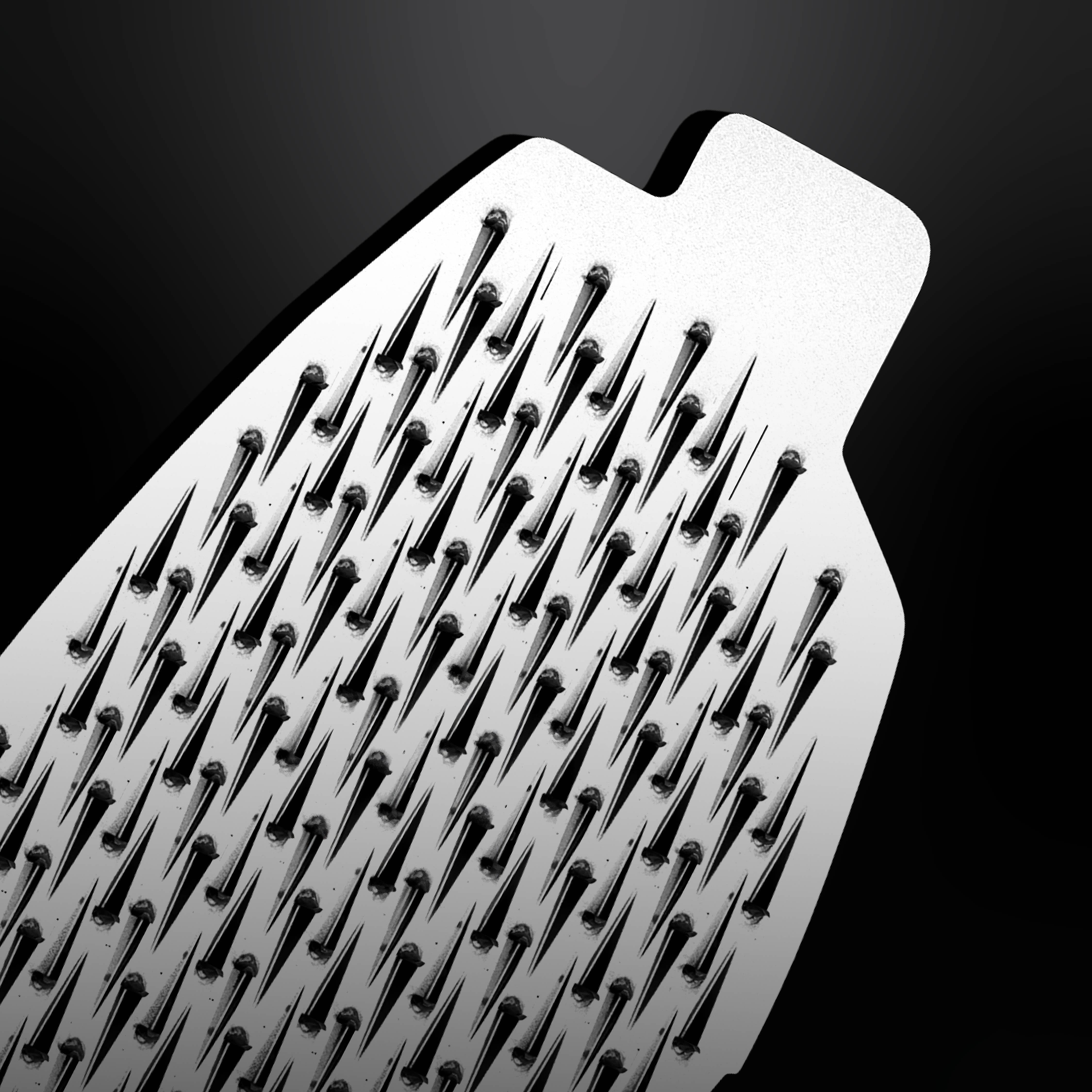

GripMetal™ Floor

GripMetal™ Floor

The Strongest, Lightest and Thinnest Flooring in The World

GRIPMetal Floor - We have created the world’s toughest floor that is resistant to impact, heavy loads and high traffic movements.

-

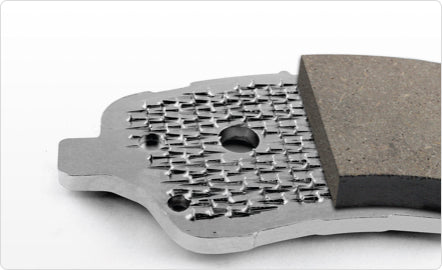

NRS

NRS

The Global Leader in Brake Pad Technology

NRS Brakes created the world’s longest lasting brake pad. NRS was the first to recognize and address the dependability issues inherent in existing aftermarket brakes.

-

NUCAP Energy

NUCAP Energy

Engineered Metal Surfaces

NUCAP Energy is the material manufacturer and a pioneer in promoting the use of GRIPMetal™ in heat transfer processes.

-

Rothoblaas

Rothoblaas

Materials for Timber Construction

Rothoblaas develops products dedicated to professionals of timber construction: carpenters, engineers, architects and installers of fall protection systems.

-

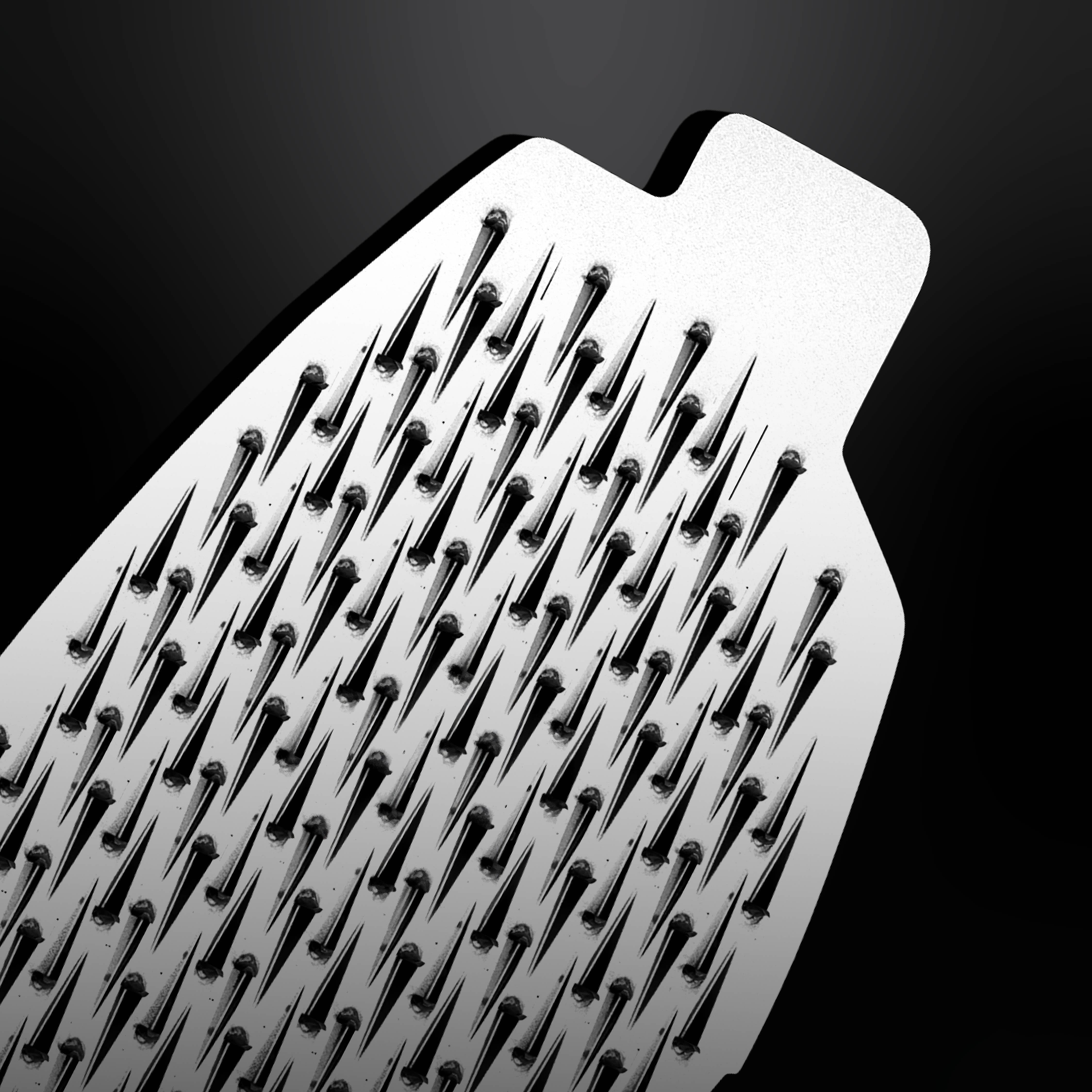

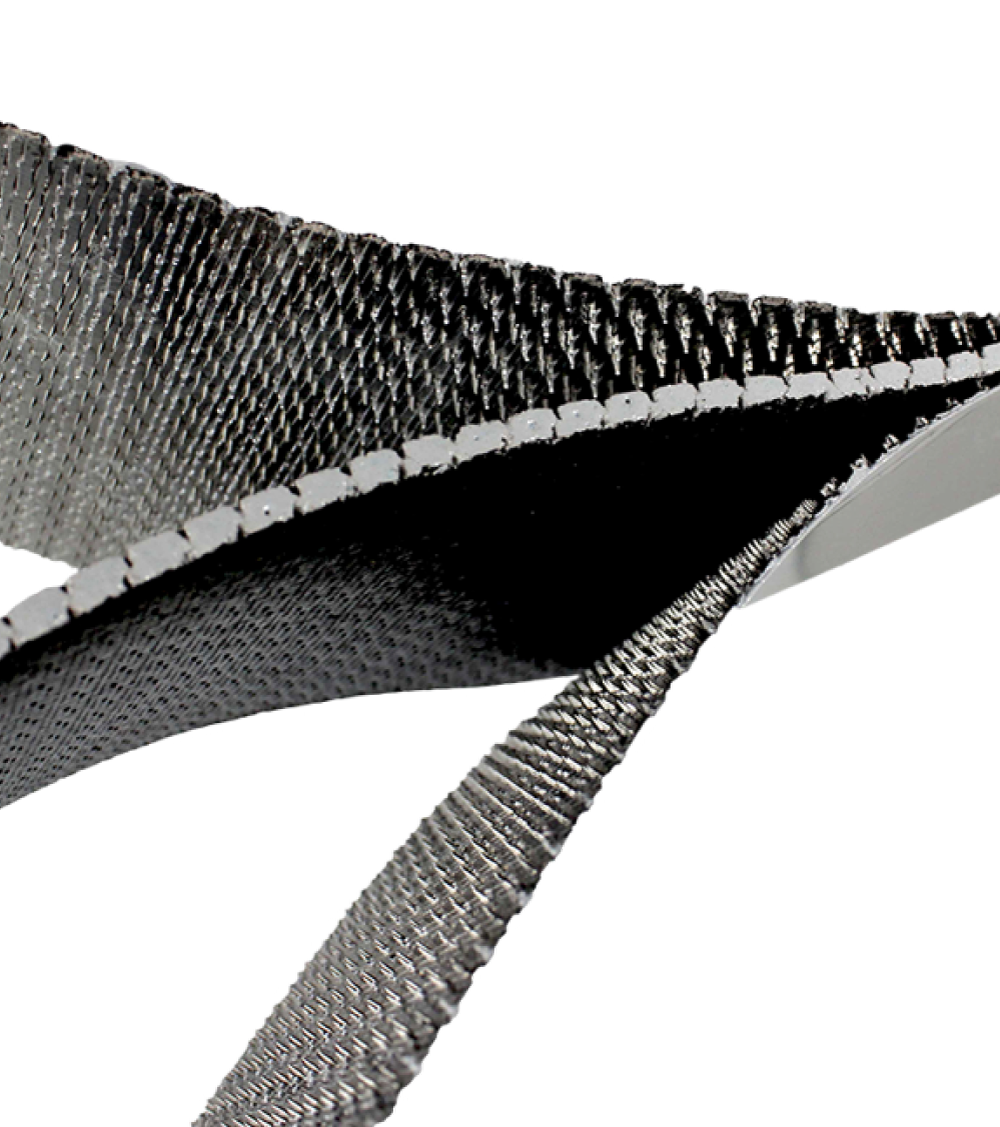

Flexible Mending Plate

Flexible Mending Plate

Strengthens Your Build with Fewer Fasteners

Flexible Mending Plate - Greatly increasing Shear strength. Utilizing thousands of micro-hooks to provide a mechanical attachment. Ideal for decks, subfloors, timber structures, framing or furniture.